Platit

Coating Machines

PLATIT are a leading manufacturer of highly advanced coating machines that are based on plasma generating PVD technology (Physical Vapour Deposition). From their Headquarters near Solothurn in Switzerland, Platit operates on a global basis and has supplied more than 550 coating installations world-wide into no less than 38 different countries.

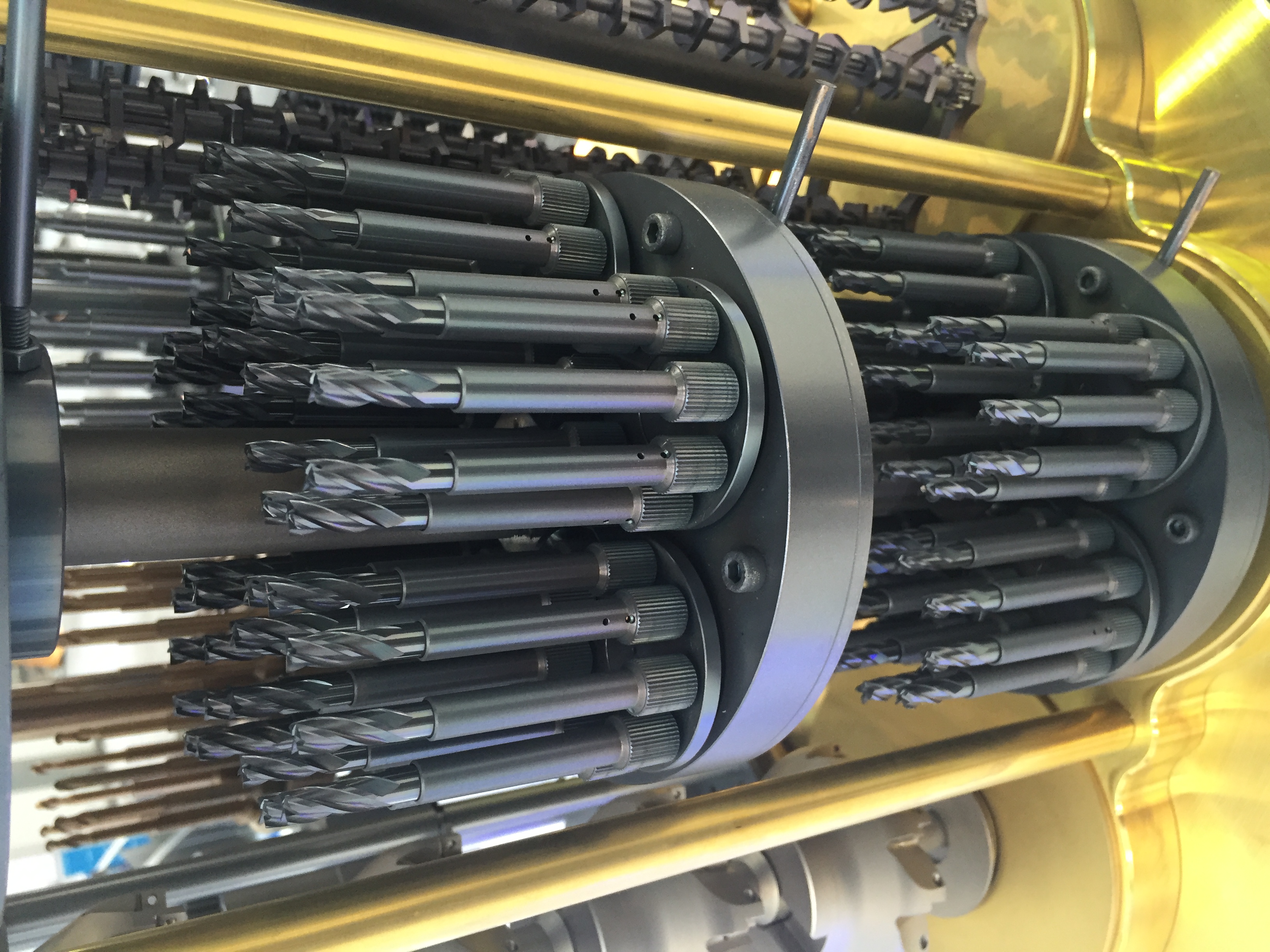

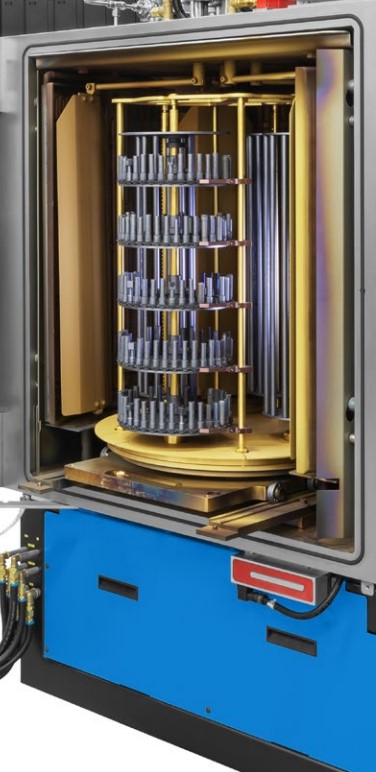

PLATIT offers complete turn-key solutions including all necessary peripheral equipment and technologies for surface pre-treatment: Platit coating machines work on the basis of the Conventional Cathodic ARC principle and the revolutionary LARC® (LAteral Rotating Cathodes) and CERC® (Central Rotating Cathodes) technologies. These technologies are patented and are unique.

One of the main applications for Platit coating machines is the coating of cutting tools (end mills, form tools, and drills) and also inserts, saw blades, hobs and broaches. Tool manufacturers can now easily and cost efficiently coat their own tools instead of relying upon expensive subcontract solutions.

THE MOST IMPORTANT REASONS FOR INTEGRATING PLATIT COATING MACHINES INTO YOUR TOOL MANUFACTURING PROCESS.

- Independence from service providers. With your own turnkey system, you will have your entire production in your own hands. The coating knowledge remains in-house.

- Save a large amount of money – subcontract coating shops charge a lot of money for what is a cheap process. Payback can be made in under 2 years.

- Speed is everything. Logistics are simplified and faster delivery times are made possible. In-house production guarantees the shortest routes, and damage caused by transport or packaging is prevented.

- Improved Quality. Even the best coating centre cannot deposit an optimum coating for all tools. It’s not possible to produce an optimum coating thickness for all tools, because coating shops mix batches in large chambers containing different tools that actually require different coating thicknesses. With your own turnkey system different tools do not have to be coated together with a universal coating, but their specific applications can be considered.

- Your own unique coatings. You need to stand out from your competition. Platit provides plug and play recipes for most coatings but with Platit machines you can develop your own coatings that guarantee you a unique selling proposition.

Platit do much more than just building coating machines; they are constantly developing new coatings for their customers’ needs and offer a full consultancy service for their end users to ensure that they are using the optimum coating for their application. The machines themselves are very user friendly and are extremely versatile. Coating is no longer a black art!

Talk to the leaders in Coating – talk to Platit!

References

Our range of machines is supplied to numerous companies all around the world and the leaders in industry use these to great affect.

We have many thousands of worldwide references but customers that we have supplied equipment to here in the UK include, amongst others: