Danobat

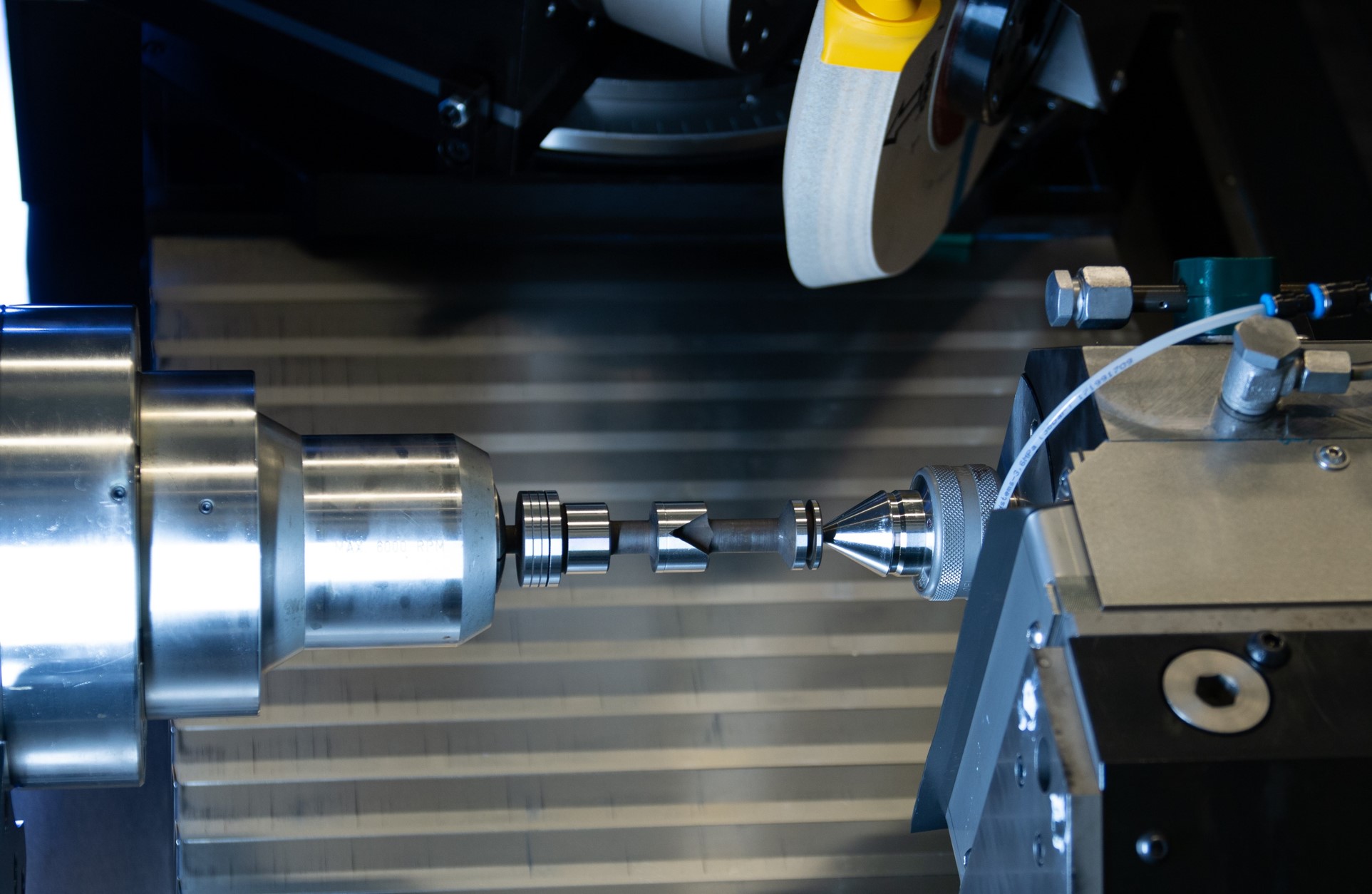

Internal, External & Combined Multi-tasking Grinding machines

Danobat was founded in 1954 and for over 70 years have been manufacturing very high precision grinding machines and today their range has grown to become one of the largest from a single manufacturer. Danobat's range comprises of both horizontal and also vertical grinding machines with internal, external, unround profile grinding and radii grinding capabilities.

Danobat were forerunners in creating a group of machine tool manufacturers to partner together way back in 1954. Indeed the Danobat name means All Together and derives from the Basque language Danok (All) and Bat (together). Today Danobat has grown into a giant amongst grinding machine manufacturers with a turn-over in the region of some 200 million Euro's. The Danobat group, that employs over 700 people globally, now includes Hembrug, the Dutch leader in manufacturing finish hard turning lathes and also Overbeck who are based in Herborn, Germany, and purchased by Danobat in 2003, who make internal, external and radius grinding machines.

Danobat's internal grinding machines are capable of grinding bores down to 1mm in diameter with a sub-micron capability and covers for machines with multiple grinding spindles (up to 4 in the case of internal grinding) and machines that can also grind faces and radii as well as OD and ID work.

Danobat UK who are located in Peterborough, and employ around 15 engineers, provides locally based expertise for after sales service support for all Danobat machines. Danobat employs around 750 people IN TOTAL and operates globally with machine tool manufacturing plants in Spain, Germany and Holland, and with tech-centers in Spain, USA, Holland, Germany, Italy and China. The tech centers are equipped with the latest machines for grinding and hard turning components and are capable of undertaking test machining to confirm the very best machine solutions.

Danobat's machines are used to great effect across all industries including aerospace, automotive and e-mobility, energy, hydraulics, medical, and railway etc.

Applications are numerous but include aero engine rotors, stators and cases, gear grinding, spool valves, hydraulic pump parts, piston rods, axles, diesel injector parts, axial and radial piston pumps, gear pump shafts, gearbox shafts, artificial hip joints, and printing and packaging rolls.

Challenges are the inspiration for Danobat

Got a Challenge?

References

Our range of machines is supplied to numerous companies all around the world and the leaders in industry use these to great affect.

We have many thousands of worldwide references but customers that we have supplied equipment to here in the UK include, amongst others: