Rollomatic

Precision CNC machines for cutting tools

Rollomatic, one of the best known, most successful, and highly respected manufacturers of multi- axis CNC grinding machines, is the machine of choice for the production of rotary cutting tools of all kinds and for non-round tools such as punches.

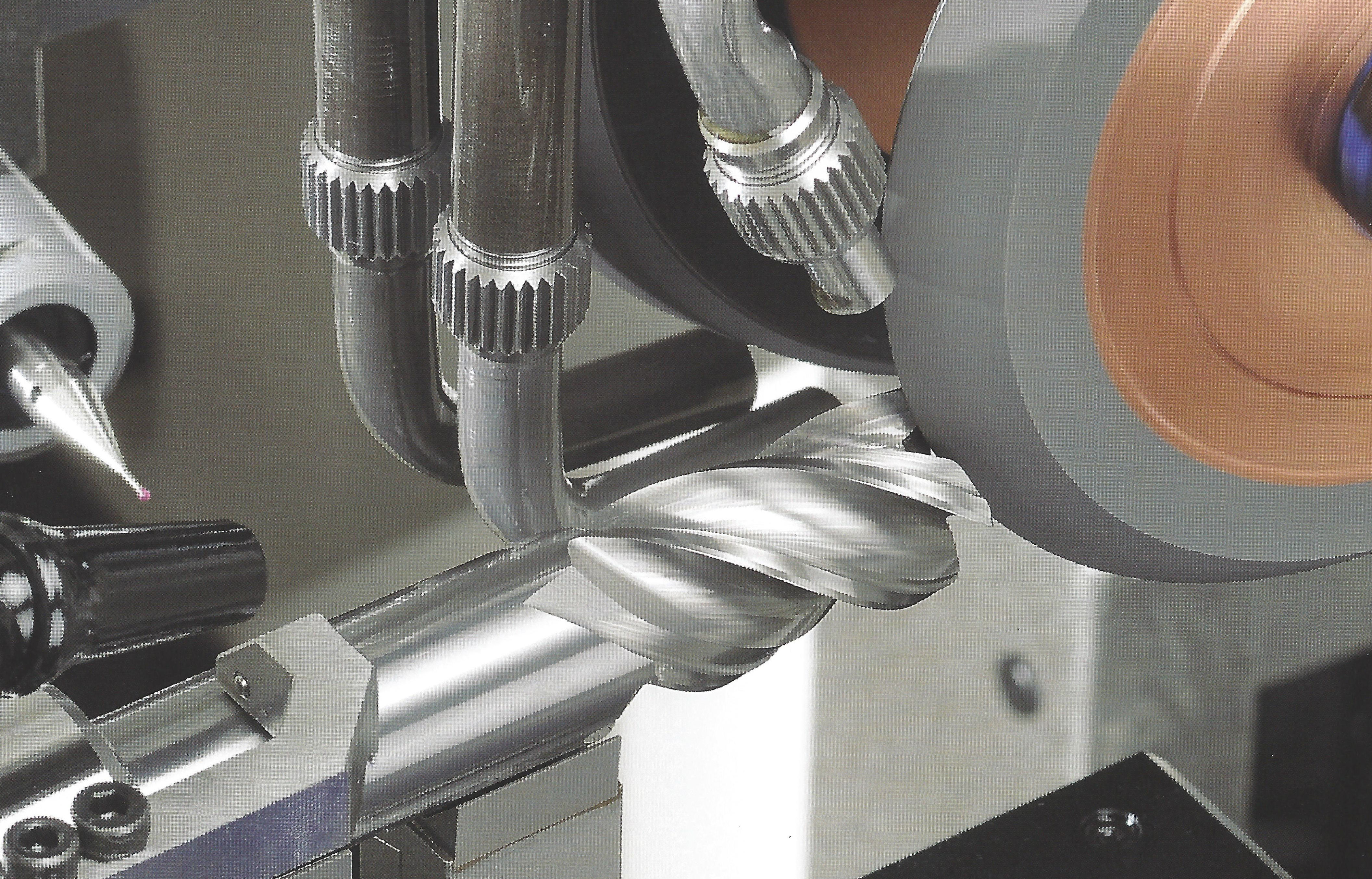

GrindSmart®machines excel at producing cutting tools of up to 20mm in diameter, and the superior Swiss manufactured quality of every Rollomatic machine is demonstrated with their industry leading 3-year unlimited hours parts and labour warranty that comes as standard on all new Rollomatic machines.

GrindSmart® machines are available with a 6th CNC axis to ensure perfect tool geometry because the contact point of the grinding wheel remains constant over the entire grinding path during production. The latest linear motor technology provides more benefits such as enhanced surface finishes and reduced maintenance costs.

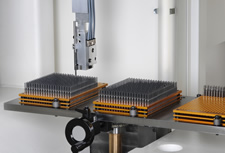

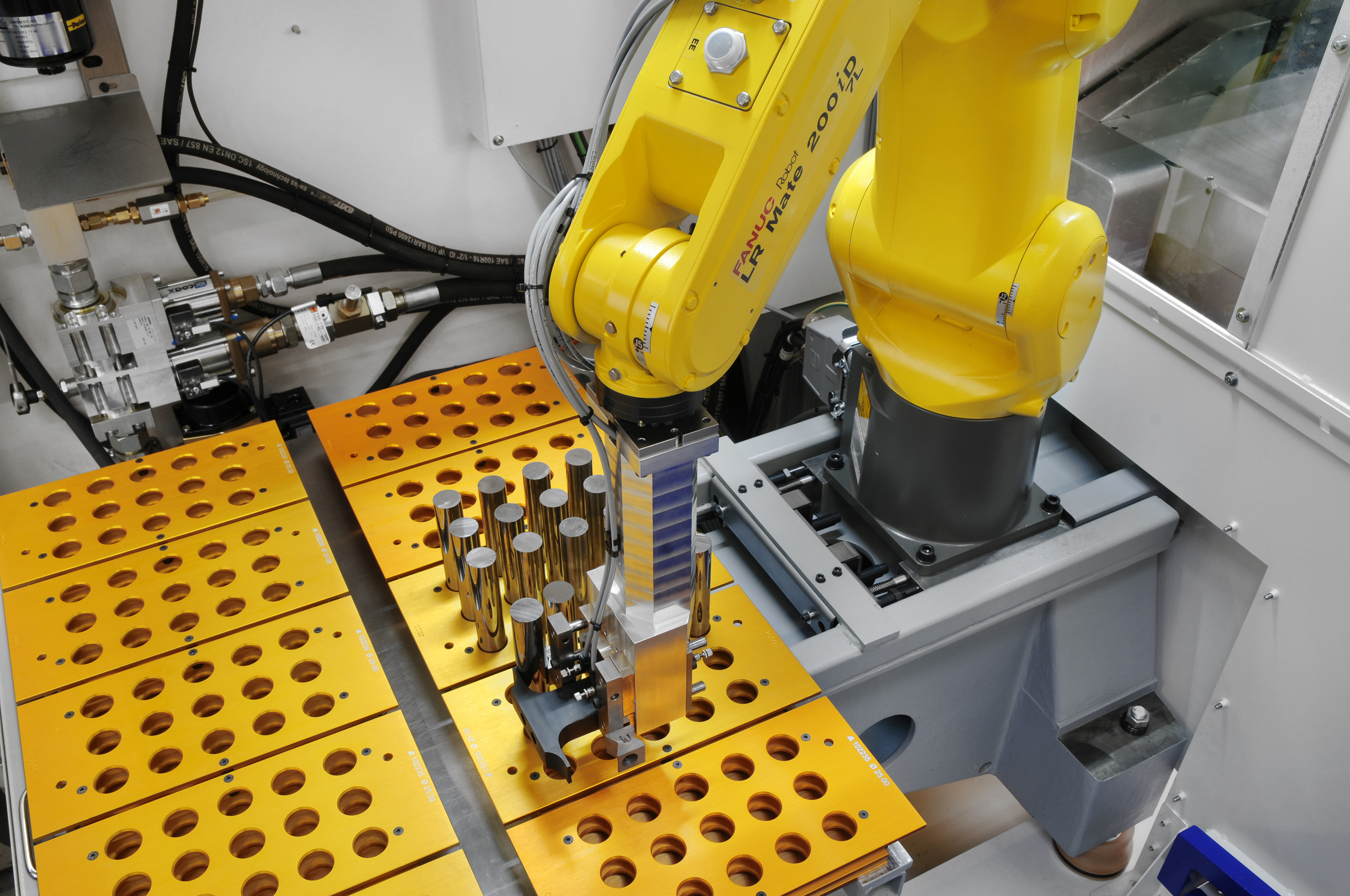

For automatic loading a variety of solutions are offered including high speed robot loaders that load 20mm dia tool blanks in around 8 seconds. 1,000 tools can be stored in pallets for unmanned running and GrindSmart® machines offer high uptime rates approaching 99% and a productivity output superior to other makes of machines without any human intervention.

The automatic changing of grinding wheels is well catered for and the ultra-compact design of the 6-position wheel changer has a capacity of 24 grinding wheels and allows for wheel changes (complete with coolant pipes) during the tool load/unload cycle to minimize dead time to further improve productivity.

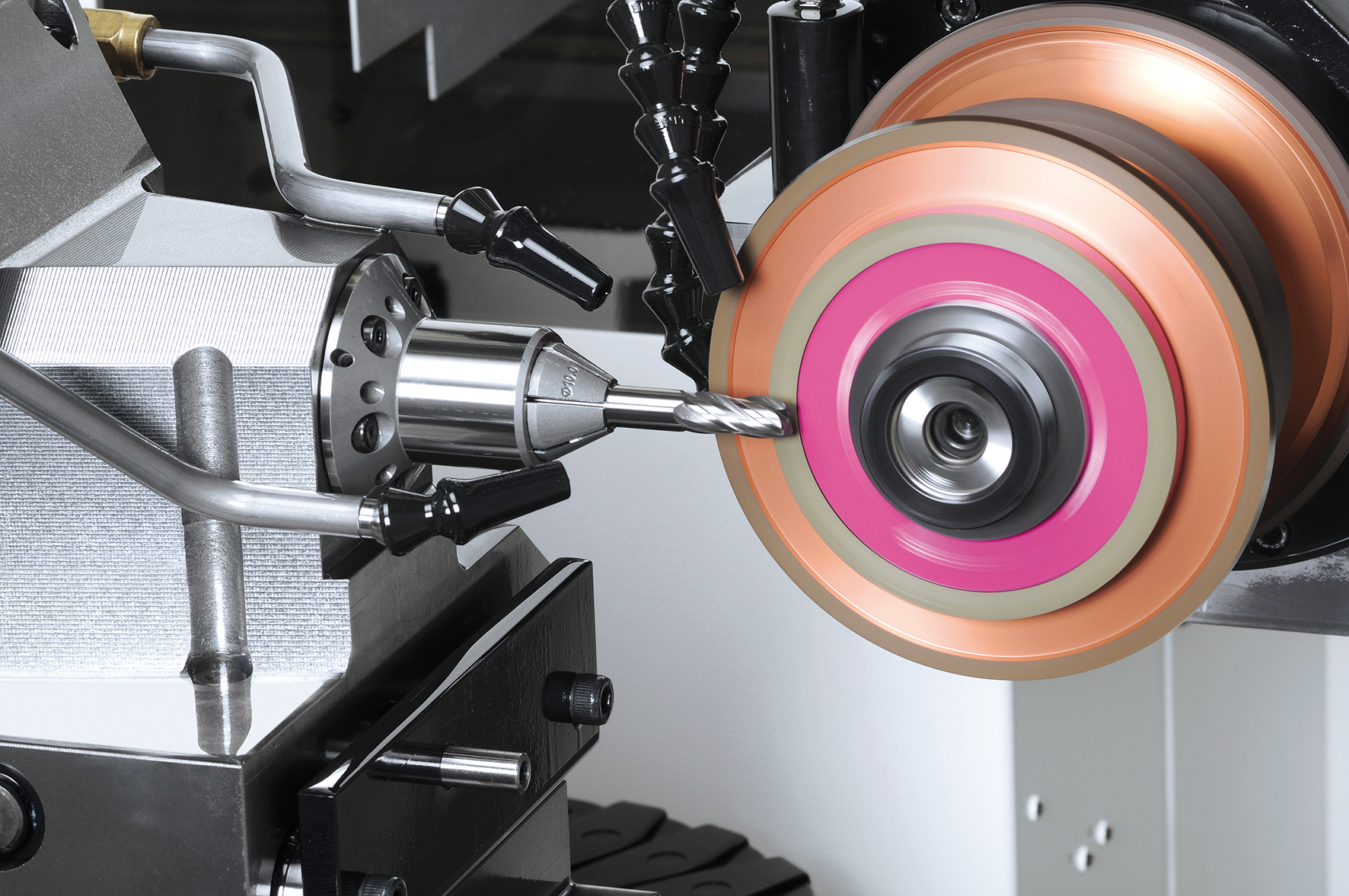

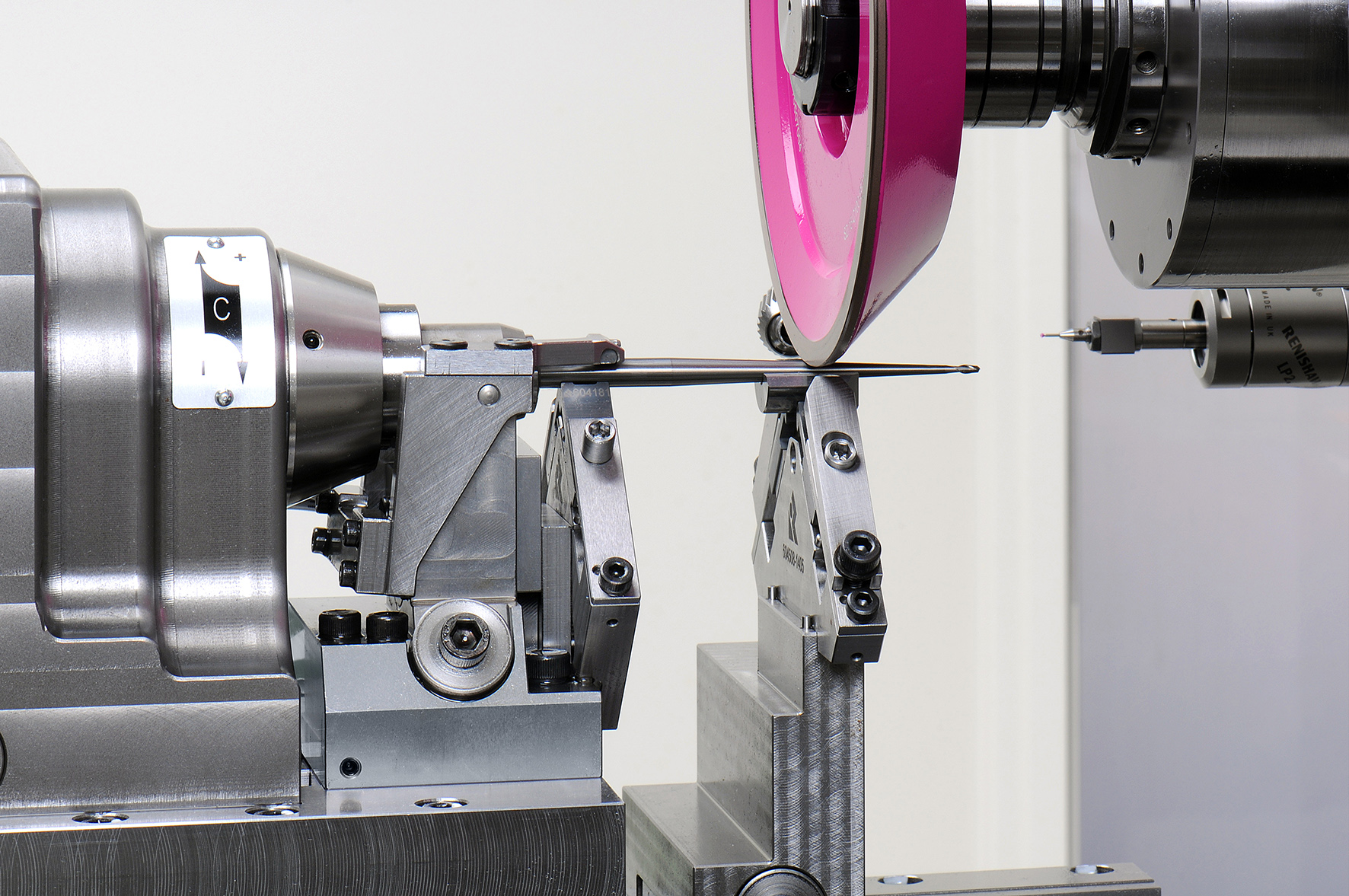

Rollomatic’s ShapeSmart® machines are ideally suited for the high performance cylindrical infeed grinding of cutting tool blanks such as drills, form tools, reamers, end mills, and punches. The ShapeSmart NP3 variant offers tool concentricity after grinding of within 0.002mm. These machines use a unique grinding process developed by Rollomatic known as "Pinch and Peel Grinding" for the production of cutting tool blanks or punches with diameters from 0.025mm up to 25mm and lengths of up to 330mm.

The ShapeSmart NP50 variant is able to grind many non-round forms such as ellipses, eccentric shapes, flats, squares, triangles or hexagons as needed on many punches. Punches are ground complete in a single automatic operation using both rough and finish grinding wheels allowing large stock removal and perfect ground finishes.

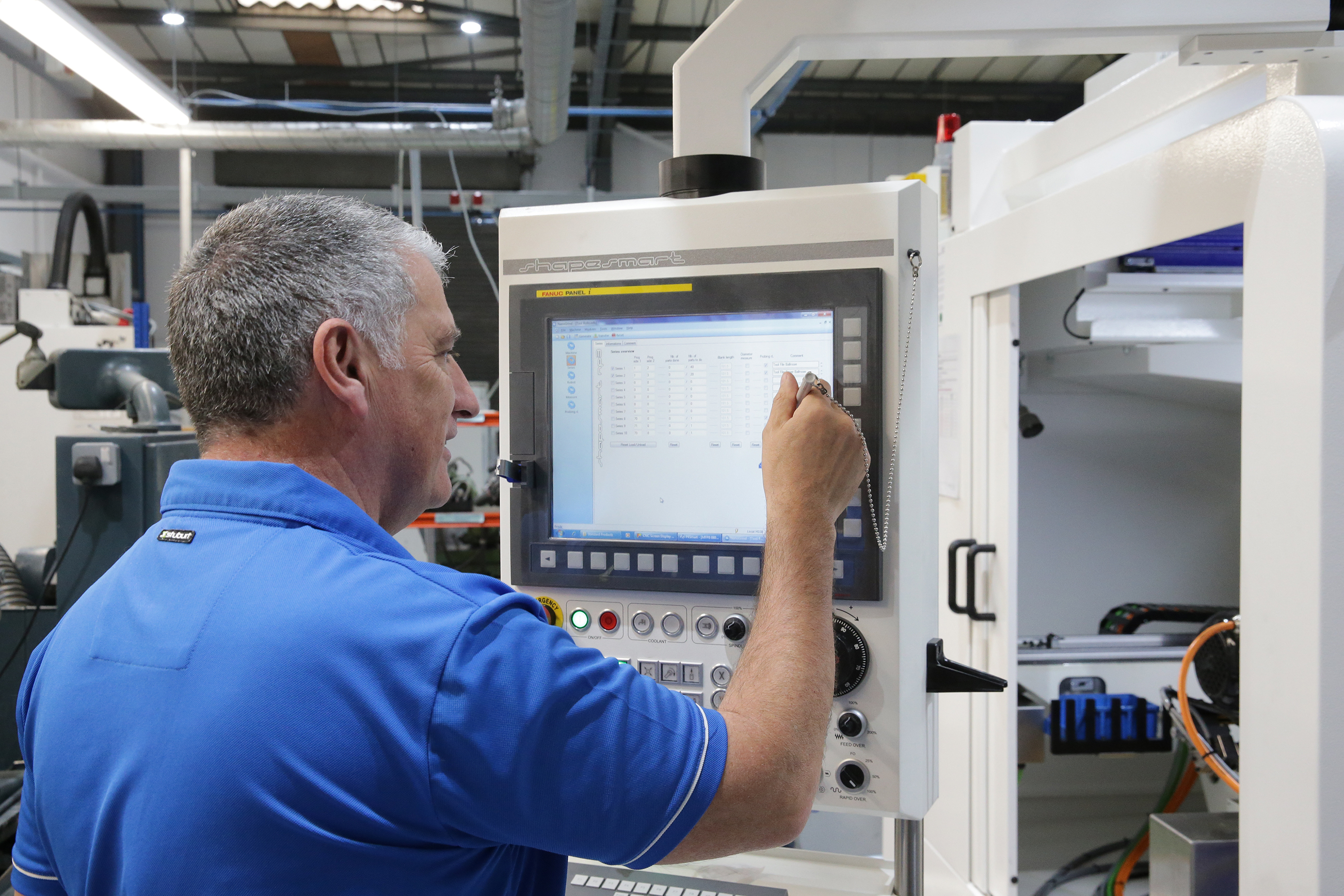

VirtualGrind® Pro is the innovative core software for the Rollomatic GrindSmart® 5 and 6 axis precision tool and cutter grinders. VirtualGrind® Pro is a user-friendly, extremely powerful and flexible software that can be used to program and manufacture any kind of standard, high-performance or special cutting tool and cutting tool software, including updates, is provided free of charge.

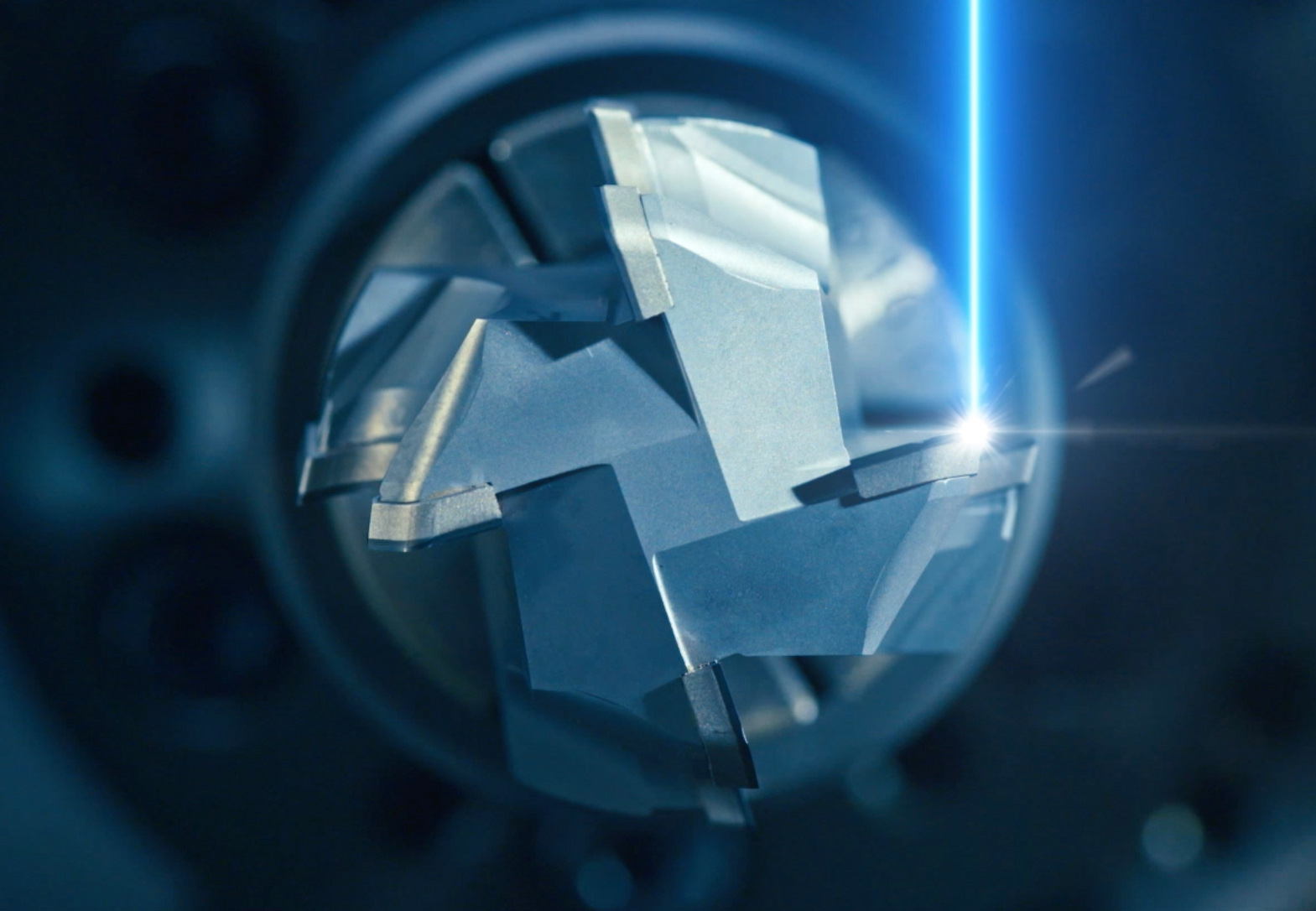

Rollomatic’s line up of high precision machines is completed with their LaserSmart 510 machine that features simultaneous 5-axis interpolation for the very high precision laser machining of ultra-hard materials such as PCD, CVD, MCD and natural diamond. The LaserSmart 510 processes multiple operations such as cutting-edge generation, chip breaker machining and cylindrical land machining, including K Lands, in one complete set-up. The LaserSmart machines can produce razor sharp cutting edges with a radius of under 1um. The LaserSmart 510 machine allows for faster production times of up to 450% compared with conventional laser machining.

The use of Rollomatic machines offers end-users key quality benefits and enables them to compete globally. The superb quality that comes from utilizing Rollomatic machines includes superior cycle times (demonstrated perfectly by the use of the ShapeSmart machines for blank production) perfect run-out tolerances of cutting tools to under 0.001mm and very fine surface finishes on ground surfaces.

To support their large number of end-users here in the UK and in Eire, Rollomatic have their own UK based service team with direct access back to the Rollomatic HQ for the same-day dispatch of all spare parts thus guaranteeing UK customers a very high level of customer support. Remember with Rollomatic you also get free software updates for life.

Call us today to discuss your application for Rollomatic machines!

References

Our range of machines is supplied to numerous companies all around the world and the leaders in industry use these to great affect.

We have many thousands of worldwide references but customers that we have supplied equipment to here in the UK include, amongst others: