Tschudin

Centerless Grinding Machines

Tschudin – One of the greatest names in grinding – continues to explore new advances in centerless grinding technology.

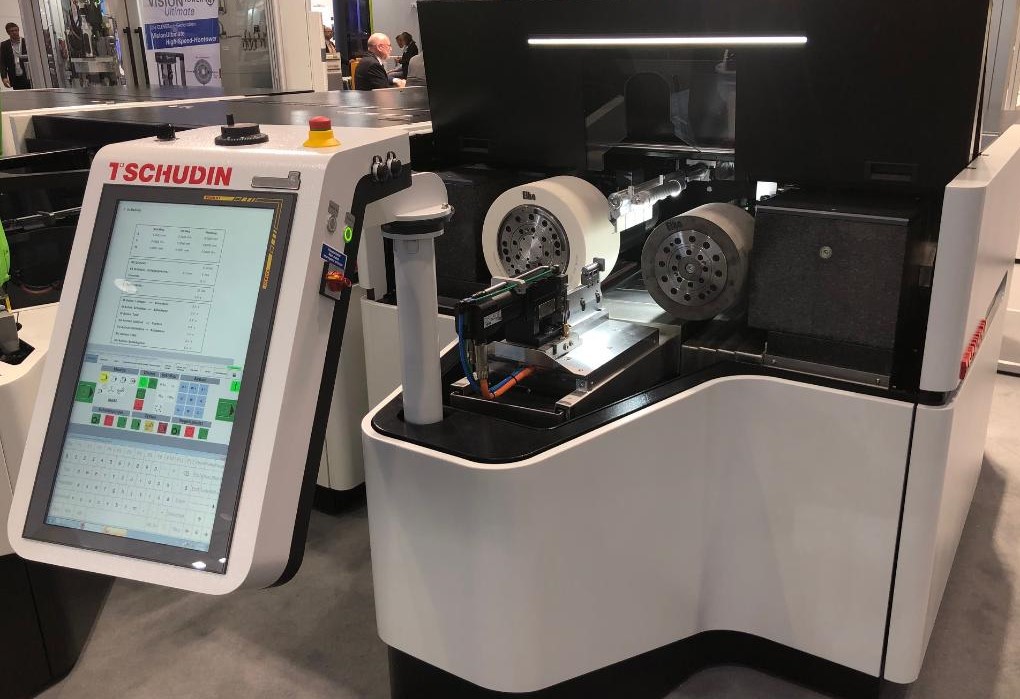

The Tschudin machines benefit from several patented features that give them major advantages over any other machines in their class and today the Tschudin Cube machine is stated as being the world’s easiest, simplest and fastest CNC centerless grinder to set-up.

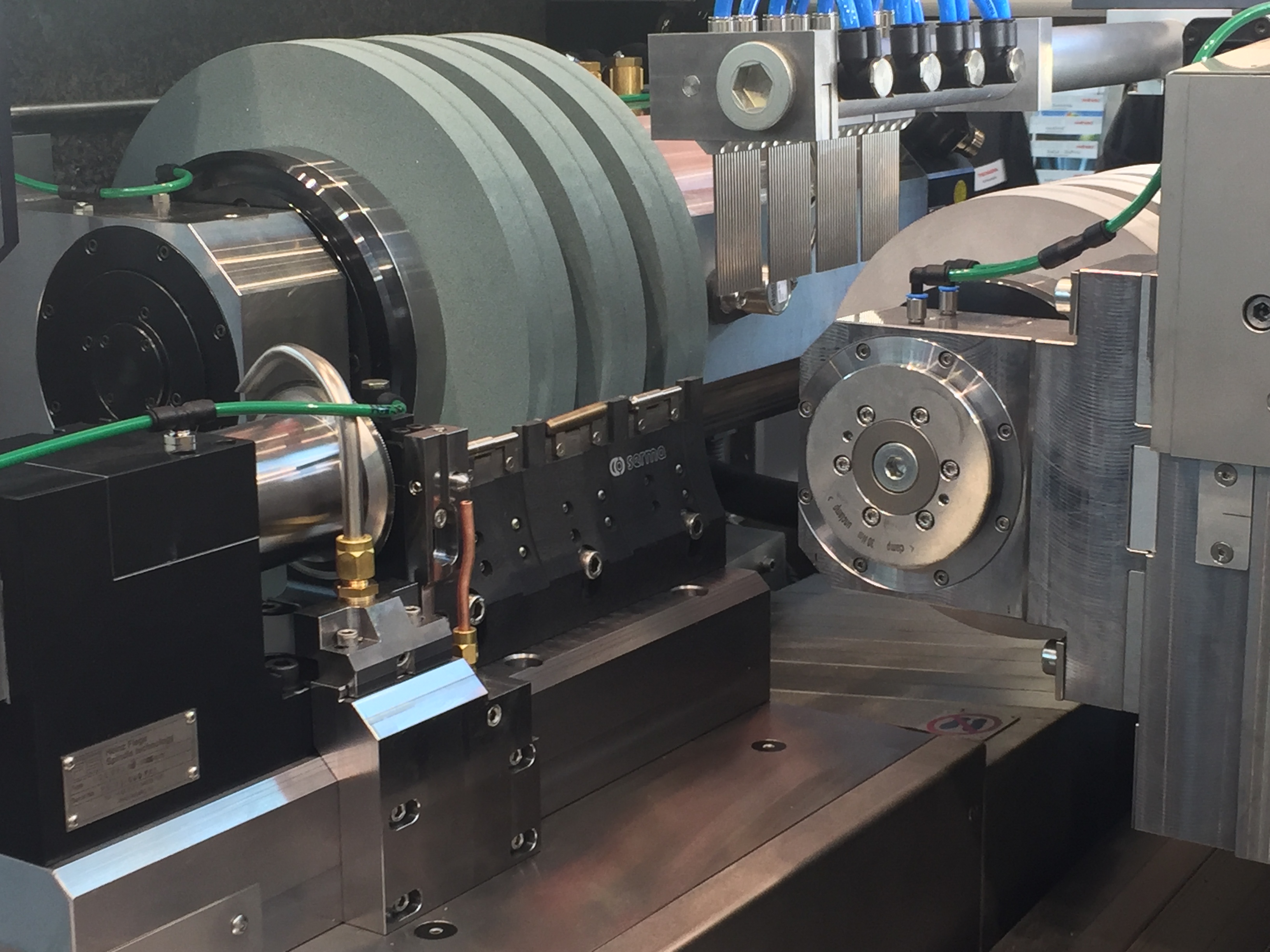

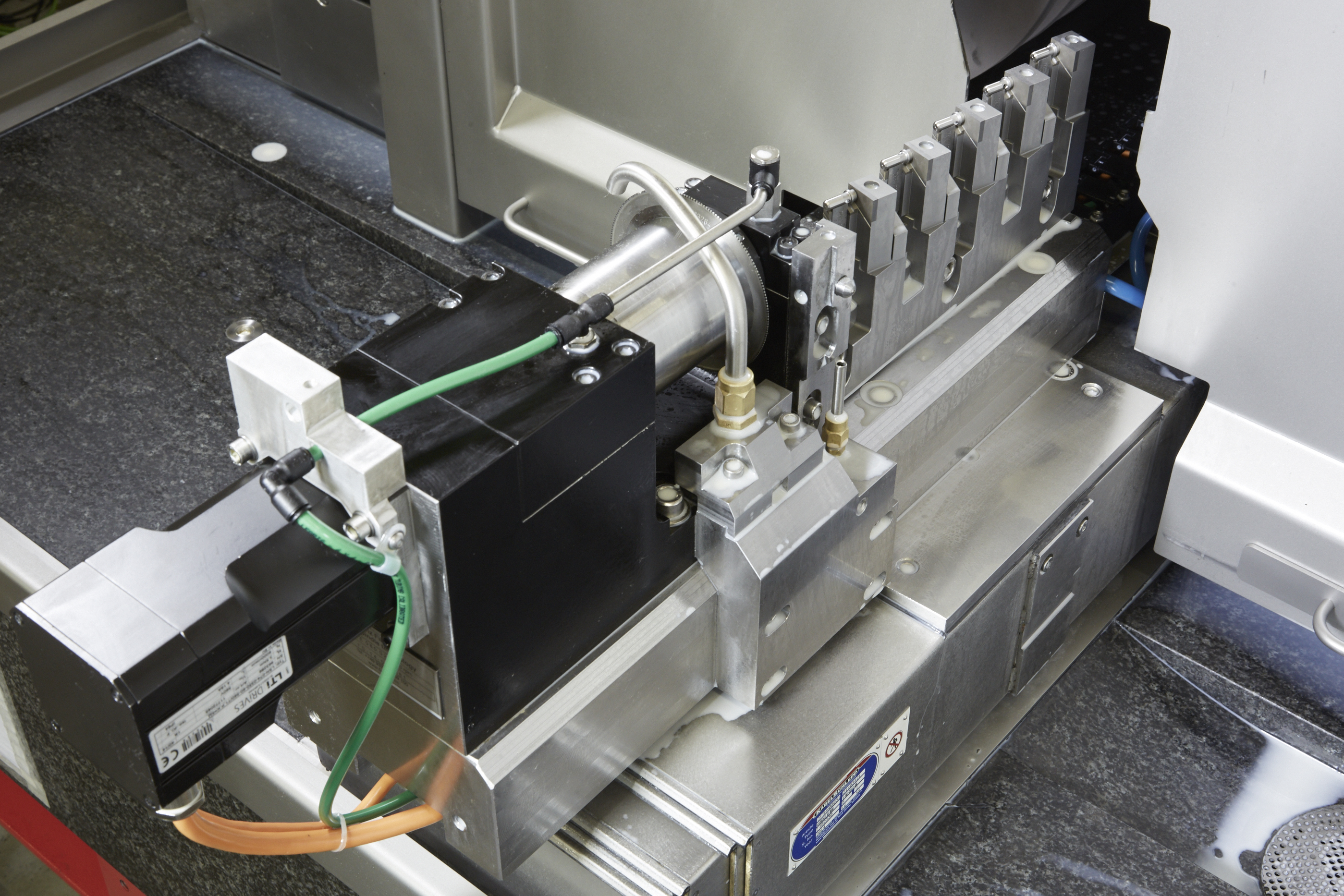

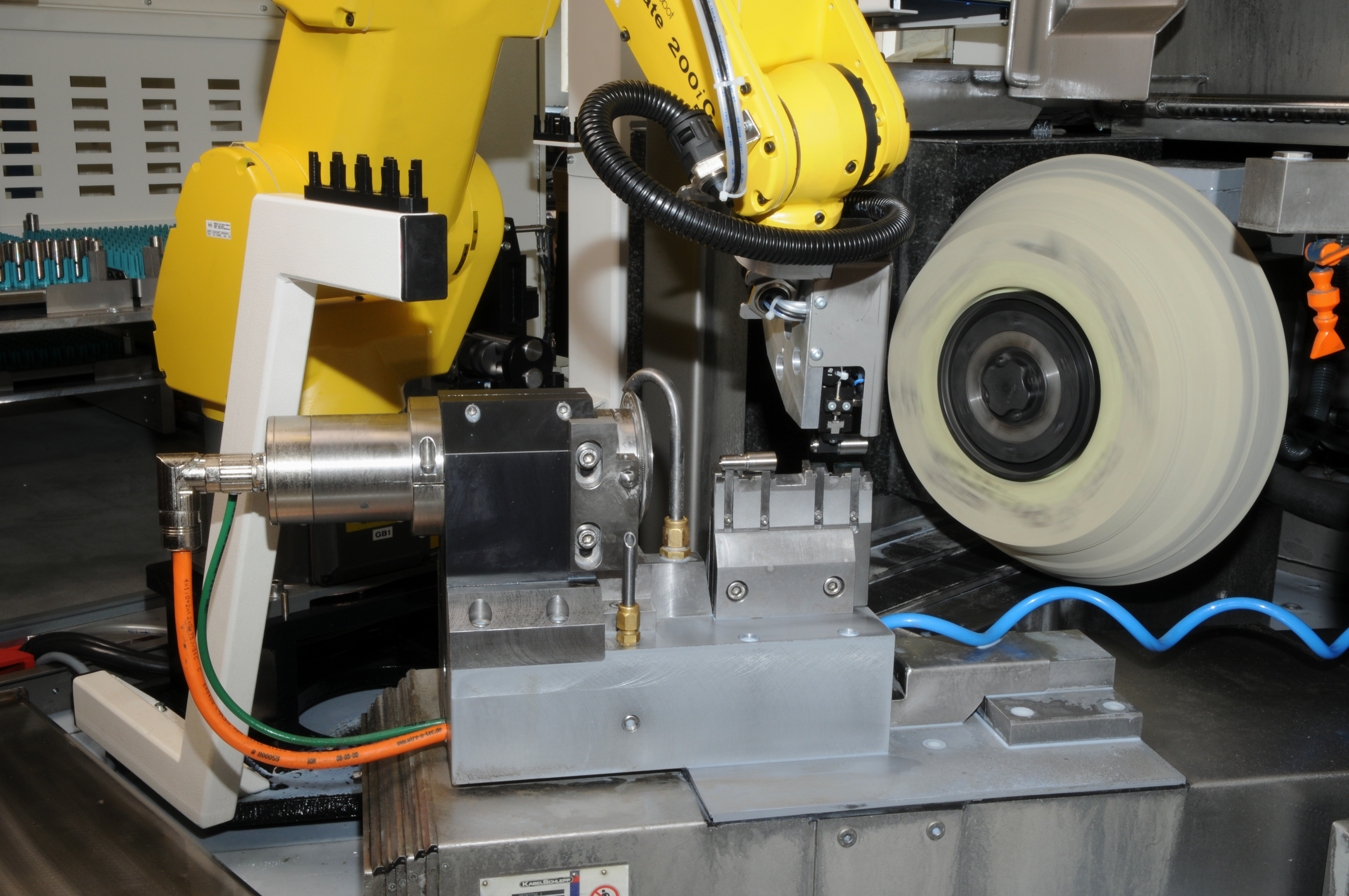

A unique feature on all Tschudin machines is also the patented movable workrest axis (W-Axis) which allows for additional grinding processes such as the highly efficient multi part grinding of several parts at a time or to split up grinding processes in the same grinding cycle to have both a rough and also a finish grind operation in one automatic set-up. Thanks to the W-axis, the loading and unloading of the workpieces is always outside of the grinding zone, allowing simplified and safe automation or safe manual loading. This feature is highly attractive for those looking to meet health & safety obligations because otherwise the hand loading of parts to centerless grinding machines can be very dangerous.

With the Tschudin’s machine base and spindle blocks made from natural granite and the optionally and newly available grinding spindle housing made from Invar, Tschudin is mastering the worst enemy of grinding which is thermal expansion due to heat variances. Ultra-precise linear slides, linear axis motors and programmable cooling supply systems are state of the art technology for the highest production demands.

The Tschudin Proline Centreless Grinder eliminates almost all of the mechanical manual procedures for set up and grinding, especially the adjustment of the workrest blade height. As a world’s first in centerless grinding, and covered by another patent, the regulating wheel on the new Tschudin machine is automatically adjusted in height by an independent CNC axis (Y-axis). The optimum grinding position of the workpiece to achieve the best possible roundness is arrived at simply by digitally adjusting the height position of the regulating wheel. During the production process, the Y-Axis will also compensate automatically for any change of grinding geometry due to wear of both the grinding and the regulating wheels. Therefore workpiece quality remains consistent.

In 1991 Tschudin were the world’s first grinding machine manufacturer to use direct drive grinding spindles to achieve less noise, lower vibrations and energy consumption and constant surface speeds with less maintenance. All axis movements are done with digital servo drives so there are no hydraulics on the machine and no thermal expansion resulting in higher precision.

For high precision plunge grinding applications Tschudin offer very productive solutions with the auto-loading and subsequent plunge grinding of 10 or more parts at a time.

Tschudin – Less = More!

References

Our range of machines is supplied to numerous companies all around the world and the leaders in industry use these to great affect.

We have many thousands of worldwide references but customers that we have supplied equipment to here in the UK include, amongst others: